brinell and rockwell hardness test difference|brinell vs rockwell chart : Brand What is The Difference Between The Brinell and Rockwell Hardness Tests? While the two tests have similarities, there are several important differences. Both test methods are suitable for the testing of soft and medium hard materials such . Classificação completa de ven.1 2024 na ESPN (BR). Saiba o desempenho de cada time.

{plog:ftitle_list}

WEBSandra Redivo, São Paulo, SP. 10,930 likes · 3 talking about this. Jornalista, pós graduada em Sustentabilidade pela Fundação Dom Cabral. Escritora,.

Brinell vs. Rockwell Hardness: Comparison table. Summary of Brinell Verses Rockwell Hardness. The Brinell and Rockwell methods fall into the group of statistical methods of hardness testing. Each method has its unique purpose, advantages and disadvantages. While several variants of hardness testing methods are available to hardness inspectors in the industry today, the Rockwell, Brinell, and Vickers hardness tests remain the .What is The Difference Between The Brinell and Rockwell Hardness Tests? While the two tests have similarities, there are several important differences. Both test methods are suitable for the testing of soft and medium hard materials such .

There are three principal standard test methods for expressing the relationship between hardness and the size of the impression, these being Brinell, Vickers, and Rockwell. For practical and calibration reasons, each of these methods is . Brinell test is better than the Rockwell hardness test because it can measure the hardness of though material which is not measurable by another test like Rockwell. Brinell test . The Rockwell test measure the depth of the indentation, while the Brinell test measures the width of the indentation. Rockwell hardness tests use a preload to establish a zero position before the main load is applied. The . Confused about Rockwell and Brinell hardness testing? Our guide explains the differences between the two methods and offers a conversion chart to switch from one to the other.

The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained. The difference between the two lies in the different heads of the hardness testers, with the Brinell hardness tester using a steel ball and the Rockwell hardness tester using a diamond. HV is suitable for microscopic . There are several differences between the Brinell and Rockwell hardness tests. One of the most significant differences is the type of indenter used. The Brinell test uses a . The Rockwell test is the less destructive alternative to the Brinell test because it uses a smaller indenter. It is the easiest and least expensive hardness test to administer because it requires very little material prep. .

Difference in Brinell and Vickers Hardness Test: In Brinell hardness test ball indenter is pressed under load on surface in Vickers square base pyramidal diamond indenter with 136 ° internal angle is pressed under .Conclusion. Brinell and Rockwell hardness tests are valuable methods for evaluating material hardness, each with its own advantages and considerations.While the Rockwell test offers simplicity and faster results, the .

Rockwell Hardness Tester. The Rockwell hardness test is distinguished by its efficiency and the minimal damage it imparts on the test specimen. This test measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload.We would like to show you a description here but the site won’t allow us.This difference in principle of Brinell and Rockwell hardness testing causes other differences like different indenter, load etc. Difference in Rockwell and Brinell hardness: In Brinell hardness test hard ball indenter is pressed under load on surface of material. It is there for set dwell time to achieve

The Rockwell hardness test was invented in 1914 by Hugh and Stanley Rockwell. It measures the hardness of materials by applying two loads with an indenter and measuring the depth of penetration. There are different Rockwell scales that use different loads and indenters depending on the material being tested, such as scales for metals, plastics . The Brinell test is better suited for softer materials, such as aluminum, copper, and brass. The Rockwell test, on the other hand, is better suited for harder materials, such as steel and titanium. The following table highlights the major differences between Brinell Hardness and Rockwell Hardness −Conclusion: The hardness test experiment was done using a Brinell and a Rockwell Testers. The data obtained was recorded and compared. The experimental and referenced values for each metal were compared. Table 2 showed that the percent differences for Rockwell Test were smaller than for the Brinell test. This concludes that the Rockwell test is .

The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .

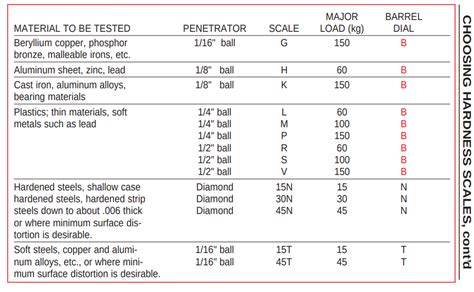

Main Differences Between Brinell and Rockwell Hardness. The size of the indenter used in the Brinell test is 10mm. It is a steel ball. Whereas the indenter used in Rockwell hardness is either a diamond cone or a spherical steel ball of less than 4mm diameter.Superficial Rockwell hardness test: In this test, a load of 15, 30, or 45 kg is applied to the surface of the material for a few seconds, depending on the hardness of the material. Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds.

Rockwell Hardness Test . The Rockwell hardness test, developed by Stanley P. Rockwell, is another widely used method for measuring hardness. It involves applying a minor initial load, followed by a major load, and then measuring the depth of penetration. The hardness value is determined based on the difference in penetration depth under the two .

The main difference between Brinell and Rockwell Hardness is mostly in their testing methodologies and the type of impact they make. Brinell hardness testing involves pressing a hardened steel or carbide ball into the material surface with a constant load, measuring the diameter of the resulting impression.Study with Quizlet and memorize flashcards containing terms like 1. Which hardness testing method measures in units DPH?, 2. In which hardness testing method does an experienced operator test the material by scratching the surface?, 3. Which hardness testing method uses a 15N Scale? and more.Difference between Brinell test, Rockwell test and Vickers test :- These are different types of tests used to determine the Hardness of a material. (1) Brinell Hardness Test :- This test is most widely used test to determine the hardness of a materi .View the full answer

wilson hardness tester parts

2. Brinell Hardness Testing Preparation . Before performing a Brinell hardness test, make sure both the test area and the indenter ball are clean and free of all lubricants. Oil or grease on the test surface or indenter .Do you know the differences between the Vickers and Brinell method? Here's the comparison: Vickers vs Brinell. + 86 755 61301520; [email protected]; Search. Home; . Brinell hardness test uses a steel or tungsten indenter of a specified size and a specified load to make an indent on the test sample. . Hardness Test Comparison: Rockwell . Because hardness varies between metals and even within the same metal group, hardness measurement methods such as Brinell and Rockwell hardness were developed to provide a common understanding of .

Explore the nuances of Rockwell and Superficial Rockwell hardness testing through an engineer's insightful journey on this informative site. . Brinell Test Block $ 300.00; HRBW Test Block $ 125.00; HR15N Test Block $ 125.00; Top Rated. HR45TW Test Block $ 125.00; HRD Test Block $ 125.00;Comparing Metal Hardness Tests include the Brinell hardness test, the Rockwell scale of hardness, and the Vickers scale of hardness. The Brinell test measures resistance to indentation but is not effective for fully hardened steel or other hard materials. The Rockwell test is fast, inexpensive, and does not require special equipment or preparation.In Brinell hardness test hard ball indenter is pressed under load on surface of material. It is there for set dwell time to achieve equilibrium, then indenter and load is withdrawn from surface. Diameter of indentation thus formed is measured. The Brinell hardness number is expressed as ratio of load and area of indentation.The Rockwell hardness is the difference calculated between the depth of the print at maximum load and its depth at preload [4]. This method, due to the fact that the prints of the cone or ball . The Brinell hardness test was performed by pressing a ball D (a steel hardened ball with a diameter d and a depth h as

Differences in Measurement Principles. Brinell Hardness Tester: The Brinell hardness tester employs a diamond indenter that is pressed into the surface of the test specimen.The diameter of the resulting indentation is measured, and the Brinell hardness number is calculated based on the applied load and the diameter of the indentation.The hardness value is typically reported using scales such as Rockwell, Brinell, or Vickers, depending on the testing method employed. Hardness is an essential property in various industries, including manufacturing, engineering, and metallurgy. Hardness provides valuable information about a material's wear resistance, strength, and ability to . General Purpose Testing: Vickers hardness testing is versatile and well-suited for general-purpose hardness testing across various industries and applications. When to Use Knoop Hardness Testing Testing Brittle Materials. Knoop hardness testing is best suited for testing brittle materials, such as ceramics, glass, and thin films.

Brinell Hardness. Relatively high loads are applied to parts via a tungsten carbide ball in this method. Unlike with Rockwell testing, Brinell tests measure the diameter of the indentation made by the ball, not the depth. A 10mm ball with an applied load of 3,000 kgf is most common for Brinell testing. Brinell tests are ideal for castings and .

disadvantages of rockwell hardness test

difference between rockwell and brinell

webOulu Skydive Center ry PL 72480 00021 LASKUTUS. Kerhotilat. Lentokentäntie 668 90460 Oulunsalo. Kirjeposti. Oulu Skydive Center ry PL 307 90101 OULU. Tiedustelut ja yhteydenotot. [email protected], 040 556 0403. Hallitus. [email protected].

brinell and rockwell hardness test difference|brinell vs rockwell chart